QEB INTRODUCTION

About QEB-System

It is an abbreviation for Quick Pre- Engineered Building System,

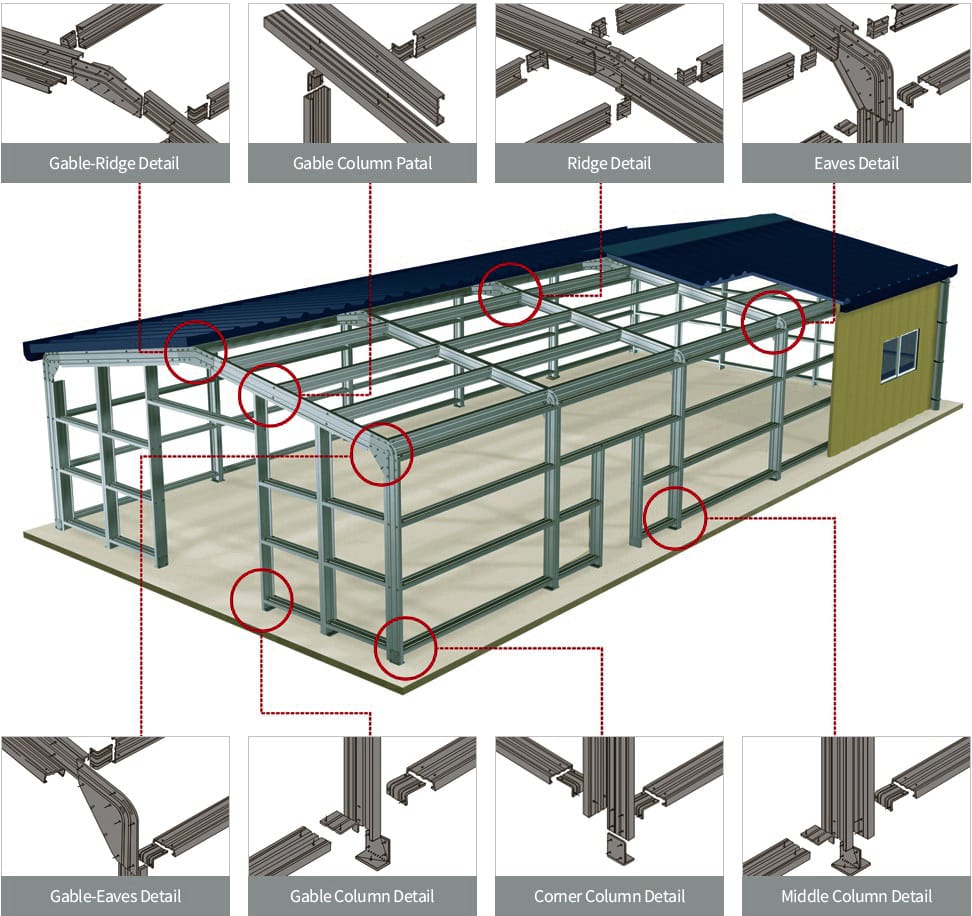

- It is a state-of-the-art prefabricated lightweight steel structure. It is a system structure that anyone can easily assemble and construct on site by simply assembling bolts according to drawings using main materials produced on an automated roll forming production line and various standardized brackets and auxiliary materials .

- The design is completely structurally designed using a dedicated program, and all materials are

made of hot-dip galvanized steel (HGI), so there is no need for separate finishing painting and it is highly durable. - By using standardized and standardized cross sections, reliability of cross section performance and quality can be increased.

- By fixing the roof slope in two types (10 degrees and 15 degrees) in consideration of aesthetics and structural stability, the

delivery time of materials can be accelerated and the construction period is shortened. - The optimized system structure reduces material consumption and

is advantageous in reducing costs and shortening the construction period through quick and accurate construction (30% reduction in cost and construction period).

Features

-

Rapid Construction: QEB systems are designed for quick assembly, significantly reducing construction time compared to traditional building methods. Prefabricated components are manufactured off-site and assembled quickly on-site, minimizing labor requirements and project timelines.

-

Customization Options: Despite their rapid assembly, QEB systems offer customization options to meet specific project requirements. Clients can choose from a variety of sizes, layouts, finishes, and architectural features to suit their needs.

-

Prefab Components: QEB systems utilize prefabricated components that are engineered and manufactured off-site. These components include structural frames, wall panels, roof trusses, and other building elements, which are designed for easy assembly and installation.

-

Modular Design: QEB systems often feature a modular design, allowing for flexibility in layout and future expansion. Additional modules or sections can be easily added to the existing structure, enabling scalability and adaptability as needs change over time.

-

Integrated Systems: QEB systems may incorporate integrated systems for mechanical, electrical, and plumbing (MEP) services. These systems are pre-engineered and integrated into the building components, reducing on-site installation time and coordination efforts.

-

Quality Assurance: QEB systems undergo rigorous quality control measures throughout the manufacturing process to ensure structural integrity, durability, and compliance with industry standards and regulations. This ensures that the final structure meets high-quality standards.

-

Cost-Effectiveness: By minimizing construction time, labor costs, and material wastage, QEB systems offer cost-effective solutions for various construction projects. Clients can achieve significant cost savings compared to traditional building methods.

-

Energy Efficiency: Many QEB systems incorporate energy-efficient features such as insulation, daylighting solutions, and energy-efficient HVAC systems. This helps reduce operational costs and environmental impact over the building’s lifespan.

-

Sustainability: QEB systems often use sustainable materials and construction practices, promoting environmental sustainability. Additionally, the modular design allows for easy disassembly and reuse of components, reducing waste and promoting resource efficiency.

-

Versatility: QEB systems can be used for various applications, including warehouses, industrial facilities, commercial buildings, educational institutions, and more. Their versatility and adaptability make them suitable for a wide range of projects and industries.