CABLE TRUNKING

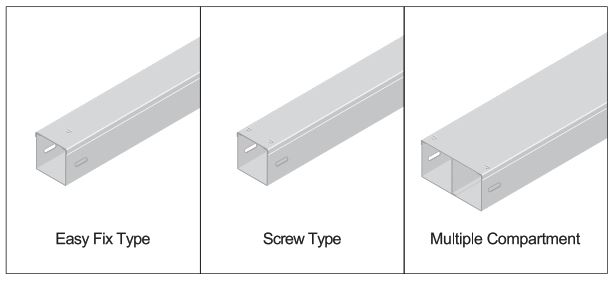

As per the specifications of the BS EN 10142, the pre galvanized steel or the hot dip galvanized steel is used in the fabrication of the GI pipes. In order to provide colours to the trunking system, epoxy polyester powder coating is provided in order to match with nay of the RAL colours. An aluminium cable tray is fit to the trunking system for the cables to rest upon. These GI pipes are also available in the screw type stainless steel trunking system.

Apart from these, the general specifications of the GI trunking, UAE, include the use of turnbuckles that help in fixing the lid for the trunking system. In order to ensure that the cables are provided with a smooth place for turns, the cable trunking, UAE, has provided the entire trunking set up with a gusseted construction and also an integral coupler. It is made sure that all the pieces that are being manufactured and produced are state of the art and does not have any kind of defect.

CABLE TRUNKING

USE OF CABLE TRUNKING :

Cable trunking is used to protect cables and provide space for other electrical equipment. They make electrical ducting and cable trunking for concealing and securing cabling

DETAILS :

Manufactures and produced under the guidelines of BS 4678 part-1, the cable trunking has been introduced to provide a system to make sure that the wiring system is managed properly and laid out without any form of mix-up. This type of trunking system was brought up to make sure that various clients were provided with the wiring at the same time instead of delivering to them individually. To put in simple terms, a trunk is simply a transmission channel between two different wires and either of these acts as the node or the switch point for the entire wiring.

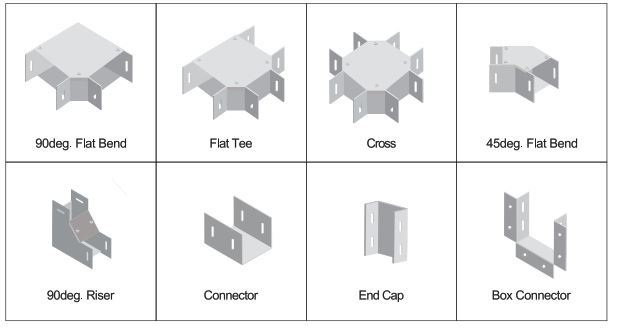

CABLE TRUNKING FITTINGS & ACCESSORIES :